Webcast

Energy Observer, a true floating laboratory

Event date

21 April 2023

Event location

Paris

Energy Observer, a source of inspiration and experience for Fountaine Pajot, allowing the development of the first production hydrogen-powered cruising catamaran.

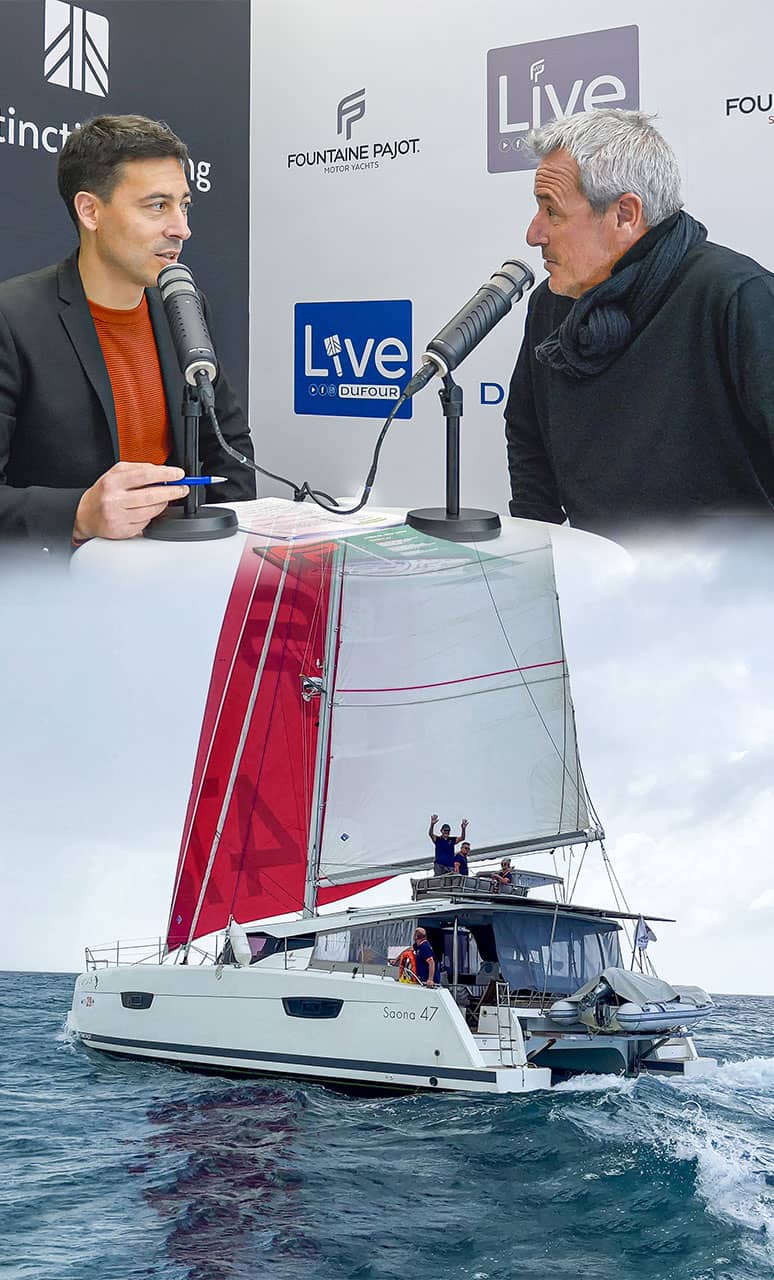

Fountaine Pajot recently collaborated with EODev, a company specialized in hydrogen solutions, to develop its zero-carbon emission boat, the Samana 59 Smart Electric REXH2. This new generation catamaran, prefiguring the future of boating, has benefited from the technologies developed on board the Energy Observer, catamaran, a true floating laboratory of new energies, which has been sailing the world’s seas for several years. In this new podcast, on the occasion of the partners’ village organized by Fountaine Pajot in La Rochelle, we meet Louis-Noël Viviès, General Manager of Energy Observer, to talk to us about the history of this legendary boat, rich of +40 years of evolution, as well as their experiences and the technical choices they had to make to achieve this project. He also talks about the interest of hydrogen as an energy source and its future in the nautical industry for the next years.

What future for hydrogen in the marine industry? | Energy Observer

16:04 min

Louis Noël Viviès, can you explain and present us what Energy Observer is?

“Energy Observer is one of the first and oldest large racing catamarans. It was originally called “Formule Tag”, the first large catamaran built by Canadair in 1983. So the boat celebrates its 40th birthday in April, which is very interesting from a life cycle analysis perspective. It was famous by Peter Blake, because he beat the round-the-world speed record at the time with this boat. It had 450m² of sail area, and weighed 15 tons. Today, Energy Observer weighs 35 tons, and it has only two small vertical wings on each side of 32m², but they are very efficient.

So it’s very symbolic that the first production cruise boat using these hydrogen propulsion technologies, with the Samana 59 Smart Electric REXH2, is from Fountaine Pajot. Because it is also here, in La Rochelle, that the famous catamaran “Charente-Maritime” was built, one of the first racing catamarans that made headlines at the time.

So this is the story of a legendary racing boat, which has been modified and lengthened countless times and which is today the first floating laboratory for renewable energies. Today, we are working on new generations of flexible solar panels, on variable pitch propellers and of course on hydrogen…

Indeed, it was a world first to have an electrolyser on a boat, back in 2017, when we launched the boat, which allows us to produce our own hydrogen on board. We have sailed more than 50,000 miles with this technology, the equivalent of two round the world tours. It is a very efficient laboratory with engineers and sailors from the merchant navy on board. It’s really very efficient.”

What are the challenges that Energy Observer had to face to implement a complete hydrogen system on board?

“It was the fact that it was really innovative, there were a lot of standards and regulations to respect. However, as we were really the first, we were quite well followed and accompanied. But very clearly, on the first departures, when we were refueling with hydrogen, with the cables laid directly on the dock by a small truck, it was not easy. We also had a lot of problems with the electrolyser to produce our own hydrogen on board, at the beginning it didn’t work, we must be clear. Today, we still have a lot of work to do on the compression, because yes we use gaseous hydrogen and not liquid, so we have to compress the hydrogen to store it. Indeed, there were no small compressors on board, so we had to design custom-made compression systems.

At each step, we had to innovate, make reliable, break and replace. But on the hydrogen part, since the boat has been equipped with a Toyota fuel cell from the automobile industry, to convert hydrogen into electricity, it is much simpler than with our prototype fuel cell. These fuel cell are subject to strong constraints, such as a marine environment, with humid and salty air, shocks, temperature variations… Not to mention fine particle pollution. It may seem trivial, but there are a lot of diesel boats in the ports, and these fine particles must not be enter the fuel cells, because that would damage the system, so we have worked a lot on air filtration systems. Not to mention the cooling system which is an exchanger using sea water as a cooler…

So everything had to be invented, it was step by step. I salute the enormous work done by the engineers on board, even if the average speed of the boat today is around 5-6 knots with peaks of 12 knots. But when we think back to the first big boat of this type, Planet Solar, a big German boat that was 125 tons and that ran only on solar energy, it only went around the world at an average of 1.8 knots.

Today, after five years, Energy Observer 1 is almost at the end of its development. We are now doing a lot of reliability work, we are trying new generations of solar panels… but of course we are still trying a lot of things in terms of hydrogen, especially everything concerning the corrosion on board.

To be honest, when we launched the boat in 2017, I didn’t think it would work so well, but it works! That’s why today we’re very proud to see production boats adopting these solutions, because we’re convinced that’s really the future, we don’t see any other solution.”

Thanks to the experience you have acquired with Energy Observer, how do you see the future of hydrogen implementation in the maritime industry?

“To be precise, we think that on the “small” boats we will use automobile technologies, for several reasons. First, because it is much cheaper because they are manufactured in large series. You should know that this year (2023-2014) Toyota has a production target of 30,000 units of fuel cells, the same one that is present on Energy Observer and the Samana 59 REXH2 of Fountaine Pajot. So we are no longer working with fragile prototype fuel cells, with a virtually unknown lifespan. We now have a track record, with extremely reliable data on the ageing of the boat and on the corrosion of the membranes. So we have life expectancies that are really becoming compatible with maritime use. Then, I think that we will use more and more these industrial fuel cells because, in addition to being inexpensive, they are very reliable, light and compact. The hydrogen will be stored in a gaseous state, because in the automobile industry it is gaseous, with pressures of up to 700 bars, which is the standard in this sector.

Of course, on very high-powered boats such as super yachts or cargo ships, which are the big projects we are working on today with Air Liquide and CMA CGM, we will switch to liquid hydrogen, cooled to -252 degrees. These are truly innovative technologies. In my opinion, we are back in a cycle of real innovations, breakthroughs and development, as we did at the time for Energy Observer 1.

However, the boundary between gaseous hydrogen, which I would qualify as standard and mass market, and liquid hydrogen, which is the future of heavy maritime transport, will become increasingly porous. We realize that the heavy truck industry is investing a lot in small liquid hydrogen tanks. But there is still a long way because behind it there is not yet the technology to process what is called “vapor lock.” When you cool hydrogen to -252 degrees there is evaporation with a loss of about 10 to 15% per day. So if you have a cargo ship that uses energy continuously, both during its navigation and dock phases, this hydrogen evaporation can be used, of course. But with a sailing boat that will spend 7 days at sea, then after several days or months at dock with nobody on board, it is less coherent to lose 15% of your tank per day. You have to have permanent consumption for it to be interesting, so in my opinion it will be reserved for professional ships, passenger boats or fishing boats. […] ”

Pour synthétiser vos propos, vous imaginez donc l’avenir avec de l’hydrogène liquide pour les navires professionnels et transport maritimes lourds, et de l’hydrogène gazeux pour des bateaux de type croisière comme le Samana 59 REXH2 ? Quand est-il des solutions de recharge ?

« Oui c’est ce que je pense. Après, bien évidemment, aucun de ces bateaux n’a d’intérêt à produire son propre hydrogène à bord, comme nous le faisons. Cela dépend donc surtout du déploiement de stations de recharge à hydrogène dans les ports. Toutefois, de l’hydrogène, il y en a des quantités industrielles partout. Pour faire 1 litre de diesel vous avez besoin de beaucoup d’hydrogène. Le Diesel et l’Essence sont fabriqués à partir de pétrole brut qui est raffiné avec de l’hydrogène. Donc dès que vous avez une raffinerie, vous avez des quantités énormes d’hydrogène.

Le problème, c’est le lien entre ces grosses quantités d’hydrogène liquide (le plus vert et décarboné possible) et comment le faire parvenir aux bateaux. La solution, c’est ce qu’on appelle un “dispenser”. C’est une station qui prend cet hydrogène liquide, le compresse à la bonne température pour qu’il devienne gazeux et stable, pour ensuite l’injecter dans le bateau. Ça ne demande pas beaucoup de place. Ce sont des investissements qui ne sont pas énormes, mais on trouve que le déploiement est long, le temps que les collectivités et les ports s’emparent du sujet. C’est toujours l’histoire de l’œuf ou de la poule, il n’y a pas de consommateur aujourd’hui, ou très peu. C’est pour ça qu’on compte beaucoup sur des gros événements, comme les Jeux Olympiques de 2024, qui veulent promouvoir l’hydrogène, afin de pouvoir créer une demande un peu soudaine qui justifierait l’investissement. La religion des Jeux Olympiques c’est que chaque investissement ait un usage derrière qui rende pérenne l’investissement, donc on compte sur cet évènement. Mais c’est un peu une bagarre de tous les jours avec à la fois les énergéticiens, qui investissent dans ces systèmes et puis avec les collectivités locales, qui aujourd’hui voit encore un peu l’hydrogène comme quelque chose de futuriste, alors que ça ne l’est pas du tout ! […]

En clair, tout ceci, c’est du concret. Et surtout ça a un usage direct et immédiat pour plein d’applications, comme avec le Samana 59 REXH2, par exemple. Donc nous sommes très heureux, on a la sensation qu’on a la même culture, qu’on a la même approche, qu’on est hyper pragmatique. […] »

Louis-Noël Viviès, Directeur Général d’Energy Observer.